Injection moulding

INJECTION-MOULDING OF SILICONE RUBBER

Currently, we have 17 injection moulding machines for silicone rubber products and 20 injection moulding machines for plastic products in our group. Since 1995, we have had a focus on liquid silicone rubber (LSR) with the result of which 16 of our 17 silicone injection machines are for LSR. Three of the silicone injection machines are 2K (LSR/plastic) and we also have 3 plastic injection moulding machine which are 2K (plastic/plastic).

In order to achieve optimal quality and efficiency in our production, we have since year 2005 had a separate company (Regoform AS) in our group. Regoform provides us and our customers with best possible mould solutions, both for 1K products and 2K products of LSR or plastic. As well as our expertise, we believe imagination and collaboration with our customers are two of the most important factors in our success.

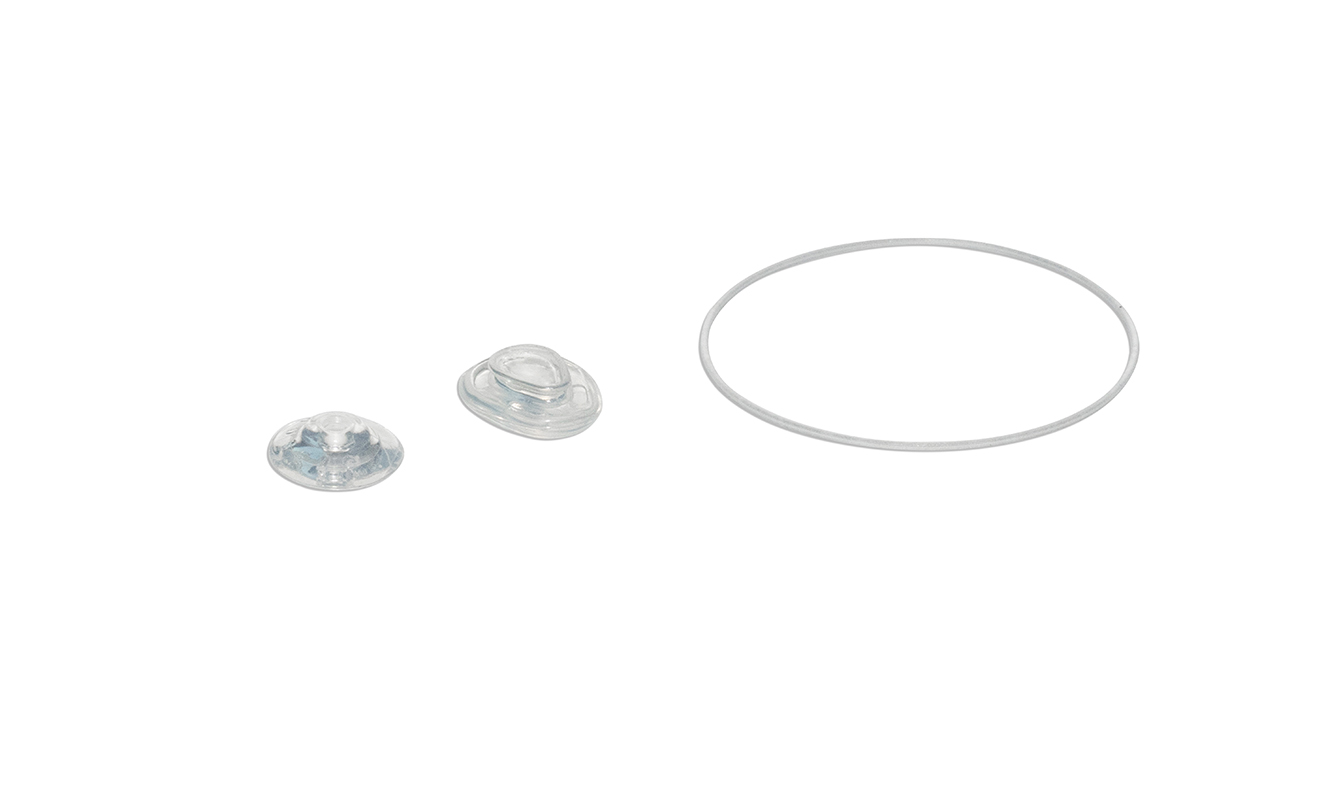

Here are some examples of injection moulded (LSR) liquid silicone rubber products that our group has manufactured:

Silicone rubber may also be suitable for Medical, Pharmaceutical, Food-processing, Electronics, Offshore, Lighting, Optical, Ovens, Mobile phones, Graphics, etc.

2K injection moulding

We can handle projects from the first prototype to large volumes in the millions with fully automatic production for true 2K moulding. Today, we have three 2K (plastic / silicone) full electric injection molding machines.

Also, we have several false 2K production lines, either with manual or robotic insertion of the plastic or metal parts in a 1K silicone injection mold which we overlay the plastic or metal parts with silicone rubber.

Our close collaboration from injection moulding concept to production guarantees competitiveness and customer satisfaction.

Rego Development ApS can assist in the development of details and give advice on product design.

Regoform A/S can assist in the design and manufacture of the tools.

Rego Development Aps and Regoform A/S are both a part of our company group, Rego Silicones Group.

Micro-moulding

Micro injection moulding of liquid silicone rubber (LSR / LIM) is an innovative system solution for injection moulding of micro-precision parts that has become popular with manufacturers, especially in the medical technology and automotive industries due to their constant changes and developments. Sipla Nordic AB can meet today’s demands for “miniature size” applications. Within the group, we have extensive experience in injection moulding of silicone parts with 0.010 mm tolerance and moulded parts as small as 0.005g